Titanium coil processing: key methods and process analysis to improve yield rate

Jul 04, 2025

Leave a message

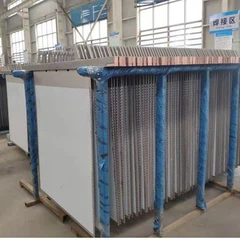

The production process of cold-rolled titanium coils is: hot-rolled coils → hot-rolled coil welding, lead-belt linking → annealing → pickling → surface grinding → rolling → cleaning → vacuum annealing → flattening, straightening → finishing → packaging.

Before cold rolling, connecting the lead strips at both ends of the strip coil is an important measure to improve the finished product yield. After hot rolling, an oxide layer will form on the surface of the titanium coil, which needs to be removed by the "mechanical descaling + mixed acid pickling" process. Under normal circumstances, the production capacity of a single-stand rolling mill can meet the production requirements of titanium coil cold rolling. However, due to the significant anisotropy of titanium, titanium coil cold rolling usually uses a multi-roll mill with a smaller diameter working roll and is rolled under high tension conditions. The finished product annealing process must be vacuum annealed to ensure the surface quality of the product. The purpose of leveling and straightening is to allow the finished titanium coil to obtain a suitable surface state and good plate shape.

The specifications of the hot-rolled coils used for cold rolling are generally (3~6) mm×(600~1600) mm, and the weight of a single coil is less than 10t. The work in the raw material preparation stage mainly includes assembling small coils into large coils, welding lead strips, cutting and updating lead strips, and cutting cracked edges. Since titanium coil cold rolling is generally carried out using a reversible rolling mill, the ends of the coil cannot be rolled normally, which will cause a large waste of titanium materials. Therefore, guide strips must be connected at both ends of the coil before cold rolling to improve the yield rate of the finished product and reduce production costs.

When the material of the leader and the strip are both pure titanium, they can be connected by butt welding; but when the material of the leader is not pure titanium (such as stainless steel, etc.), since it cannot be directly welded, it must be connected by mechanical riveting. After the cold rolling is completed, the leader needs to be removed and can be reused. In the raw material preparation stage, a coiling unit needs to be set up to assemble the hot-rolled small coils into large coils, weld the leader to the hot-rolled coil, cut the original leader from the titanium coil after intermediate rolling, and weld a suitable new leader. In addition, in order to make the leader reusable, a leader straightening unit needs to be set up to straighten the used leader, cut the head and tail, and make a new leader.

Send Inquiry