Do titanium tubes react with other metals?

Nov 14, 2025

Leave a message

Hey there! As a supplier of titanium tubes, I often get asked whether titanium tubes react with other metals. It's a super important question, especially for those in industries like aerospace, medical, and chemical processing. So, let's dive right in and explore this topic.

First off, let's talk a bit about titanium itself. Titanium is an amazing metal. It's strong, lightweight, and has excellent corrosion resistance. These properties make titanium tubes a top choice in many applications. For instance, in the aerospace industry, every bit of weight matters, and the strength - to - weight ratio of titanium tubes is just unbeatable. In the medical field, titanium's biocompatibility means it can be used for implants without causing adverse reactions in the human body.

Now, back to the main question: do titanium tubes react with other metals? Well, it depends on a few factors. One of the key factors is the presence of an electrolyte, like water or certain chemicals. When titanium comes into contact with other metals in the presence of an electrolyte, a phenomenon called galvanic corrosion can occur.

Galvanic corrosion happens when two different metals are electrically connected in an electrolyte. The more reactive metal (the anode) corrodes at an accelerated rate, while the less reactive metal (the cathode) is protected. Titanium is a relatively noble metal, which means it's less likely to corrode compared to many other metals. But when it's paired with a more reactive metal like aluminum or steel in the presence of an electrolyte, there's a risk of galvanic corrosion.

Let's take a look at some common scenarios. If you have a titanium tube connected to a steel pipe in a water - filled system, the steel, being more reactive, will act as the anode and start to corrode. The rate of this corrosion depends on several things, such as the surface area ratio of the two metals, the conductivity of the electrolyte, and the difference in their electrochemical potentials.

However, it's not all doom and gloom. There are ways to prevent or minimize galvanic corrosion when using titanium tubes with other metals. One of the simplest methods is to use insulating materials between the two metals. For example, you can use rubber gaskets or plastic sleeves to physically separate the titanium tube from the other metal. This breaks the electrical connection between them, preventing the flow of electrons that causes galvanic corrosion.

Another approach is to use coatings. Applying a protective coating to either the titanium tube or the other metal can also help. The coating acts as a barrier, preventing the electrolyte from coming into direct contact with the metals. There are various types of coatings available, such as epoxy coatings or ceramic coatings, each with its own advantages and limitations.

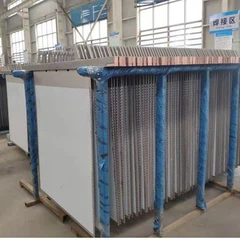

Now, let me tell you a bit about the titanium tubes we offer. We have a wide range of products, including the ASTM B338 Gr2 Titanium Tube. This type of tube is made from Grade 2 titanium, which is known for its excellent corrosion resistance and good formability. It's widely used in applications where corrosion is a concern, such as in chemical processing plants.

We also have Factory Sells High Quality Titanium Elbow. These elbows are precision - made to ensure a perfect fit in your piping systems. They're made from high - quality titanium, which means they can withstand harsh environments and high pressures.

And if you're looking for something a bit different, we offer Titanium Square Tube. Square tubes have unique applications, especially in structural and architectural projects. Their shape provides additional stability and can be used in creative ways to build frames and supports.

In industries where titanium tubes are used in combination with other metals, proper design and maintenance are crucial. Engineers need to carefully consider the potential for galvanic corrosion when designing a system. They should choose the right metals and take appropriate measures to prevent corrosion. Regular inspections are also important to detect any signs of corrosion early and take corrective action.

For example, in a chemical plant, the pipes are constantly exposed to corrosive chemicals. If a titanium tube is connected to a copper pipe without proper protection, over time, the copper may start to corrode, which can lead to leaks and system failures. By following the best practices for preventing galvanic corrosion, these issues can be avoided.

In conclusion, while titanium tubes can react with other metals under certain conditions, with the right precautions, these reactions can be managed effectively. Whether you're in the aerospace, medical, or chemical industry, our high - quality titanium tubes can meet your needs. We're committed to providing the best products and ensuring that you have all the information you need to use them safely and effectively.

If you're interested in purchasing titanium tubes or have any questions about their compatibility with other metals, don't hesitate to reach out. We're here to help you make the right choices for your projects.

References

- "Corrosion Basics" by the National Association of Corrosion Engineers (NACE)

- "Titanium: A Technical Guide" by ASM International

Send Inquiry