Molybdenum Crucible

Density: ≥ 9.8g/cm3

Appearance: Bright

Production raw material: Mo-1 molybdenum powder

Operating temperature: 1100 ℃~1800 ℃

Purity: Mo≥99.95%

Main applications: metallurgical industry, rare earth industry, monocrystalline silicon, etc

Products Description

Molybdenum crucibles are produced using Mo-1 molybdenum powder. Due to the high melting point of molybdenum (2610 ℃), their operating temperature ranges from 1100 ℃ to 1700 ℃. As a result, molybdenum crucibles are widely used as core containers in industrial furnaces-such as sapphire single crystal growth furnaces, quartz glass melting furnaces, and rare earth smelting furnaces-where the working temperature generally exceeds 2000 ℃. This is especially true for sapphire single-crystal growth furnaces, where molybdenum crucibles with high purity, high density, no internal cracks, precise dimensions, and smooth inner and outer walls play a crucial role in ensuring the success rate of seed crystallization, maintaining quality during crystal pulling, preventing sticking during de-crystallization, and extending service life during sapphire crystal growth.

AFDD Arc Fault Protection Circuit Breaker

Product name

Graphite Customization Graphite Crucible for Optical Vacuum Coating

Material

Graphite

Color

Black

Type

Crucible

Size

customization

Package

Vacuum package

Place of Origin

China, Jiangsu

MOQ

10 PCS

Advan

Durablerable

Usage

evaporation coating

Machining molybdenum crucible

Machining molybdenum crucibles are mainly small-sized crucibles, which are made by machining molybdenum rods through lathes.

Spinning molybdenum crucible

Spinning is a pressure processing method used to form thin-walled hollow rotary parts. It is achieved by using industrial feed mechanisms, such as spinning wheels or rods, to apply pressure to a metal blank that rotates along the same axis as the core mold. This causes continuous local plastic deformation, forming the desired hollow shape. A spinning molybdenum crucible is a thin-walled crucible formed by spinning a molybdenum plate as a whole. This process allows for the production of large-sized thin-walled crucibles.

Sintered molybdenum crucible

A sintered molybdenum crucible is made by adding a molybdenum powder mixture into a mold and pressing it into an initial billet. This billet is then machined by turning to form a coarse billet, which is placed in an intermediate frequency sintering furnace. Hydrogen gas is introduced, and the billet is heated to a temperature of 1900 ℃ for 30 hours. Afterward, water circulation is used to cool the billet for 9-10 hours until it reaches room temperature. Finally, the billet is heated to 1600 ℃ for 1-3 hours, taken out, and forged into the shape of a crucible. The sintered billet is then machined to form a high-quality final product.

comparison of Different process crucibles

| Production process | Machining molybdenum crucible | Spinning molybdenum crucible | Sintered molybdenum crucible |

| Purity | 99.95(%) | ≥99.95% | 99.95(%) |

| density | ≥10.2g/ cm3 | / | ≥9.8g/ cm3 |

| Height | 10-200 | / | 100-1000 |

| Diameter | 10-100 | / | 100-600 |

| Diameter tolerance | +/-5.0 | / | +/-0.5 |

| Height tolerance | +/-5.0 | / | +/-1.0 |

| Thickness | 1-20 | / | 8-20 |

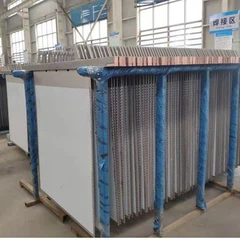

Picture Show

Please let me know your needs through any of the following contact methods.

Our address

Wenquan Industrial Park, Maying town, Baoji High-tech Development Zone, Shaanxi province

Phone Number

+8618392759938

Hot Tags: molybdenum crucible, China molybdenum crucible manufacturers, suppliers, factory, m7 titanium bolt, molybdenum material, stainless steel cathode plate, cnc machined titanium parts, molybdenum target, titanium tee

You Might Also Like

Send Inquiry