Gr1 Titanium Plate

Grade:Gr1

Ti (Min):90%

Model Number:Gr1 Gr2 Gr5 Gr7 Gr9

Processing Service:Bending, Welding, Decoiling, Cutting, Punching

MOQ:5kg

Surface:Polished

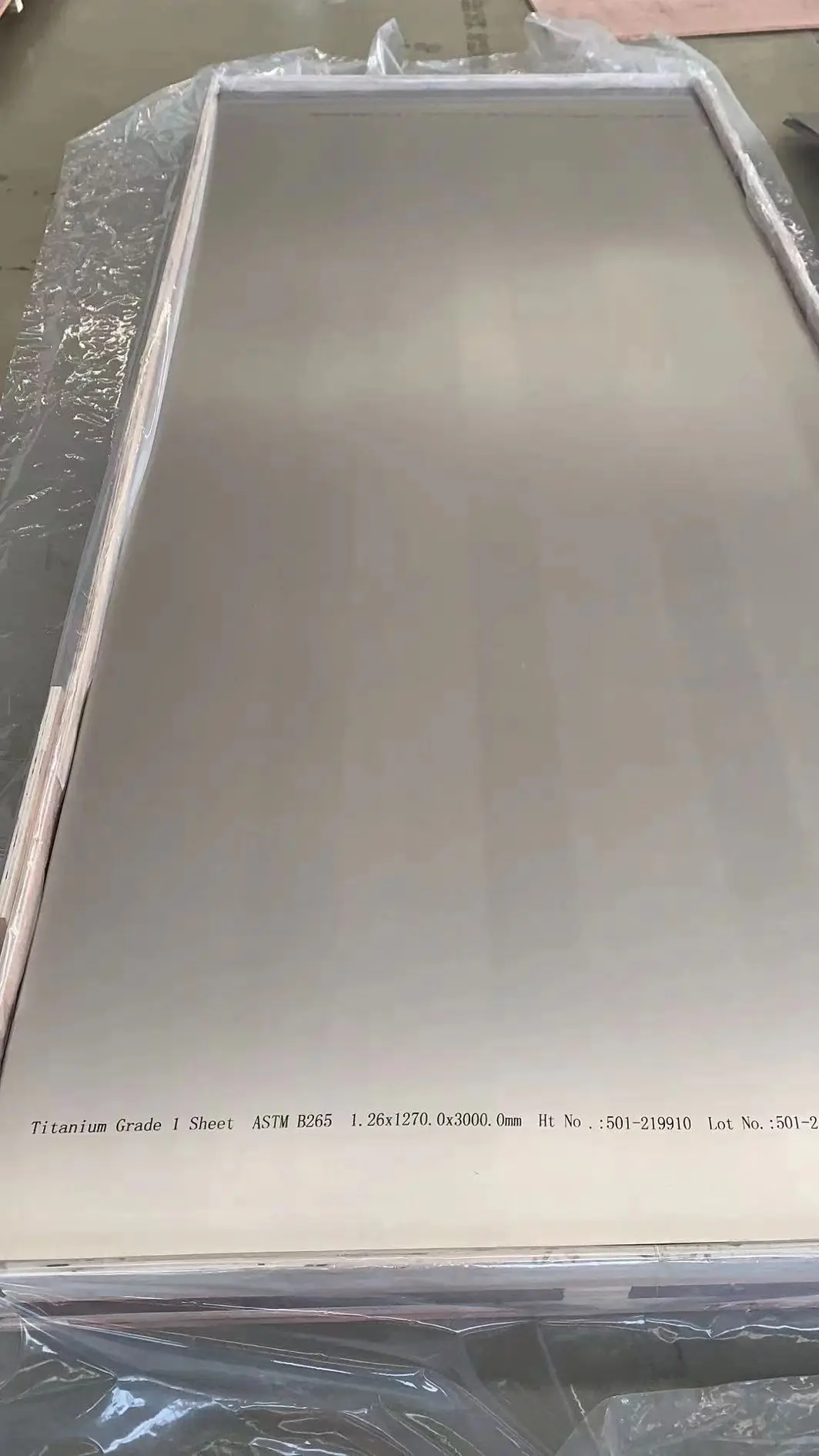

Standard:ASTM B265 SB551/SB551-M

CERTIFICATION:IS09001

Products Description

Gr1 titanium alloy is a higher purity titanium alloy, also known as Ti-Gr1 or ASTM B265 Gr1. It is composed of pure titanium (more than 99.5% titanium content) and other impurity elements such as nitrogen, oxygen, carbon, hydrogen and iron

1. Chemical composition: The chemical composition of Gr1 titanium alloy is very simple. It is mainly composed of pure titanium, of which titanium content accounts for more than 99% of the total weight. It also contains trace amounts of iron, carbon, nitrogen, hydrogen, oxygen and other elements.

2. Physical properties: Gr1 titanium alloy has excellent physical properties, such as low density (4.5g/cm³), low thermal expansion coefficient, light weight, and strong corrosion resistance.

3. Mechanical properties: The mechanical properties of Gr1 titanium alloy are relatively weak, and its tensile strength is only about 280MPa. However, it has good plasticity and processability, and is easy to cold and hot forming.

4. Hot processing: Gr1 titanium alloy can improve its mechanical properties through heat treatment. Methods such as hot rolling, hot extrusion, hot processing, forging, etc. can increase its hardness and strength and improve its use effect.

5. Application fields: Gr1 titanium alloy is widely used in aviation, aerospace, shipbuilding, marine engineering, chemical equipment, medical equipment, sports equipment and other fields, mainly because of its good corrosion resistance, high strength and lightweight.

In short, Gr1 titanium alloy is a high-quality material with excellent physical and chemical properties. It is widely used in various fields to meet people's requirements for material performance.

GR1 GR2 titanium alloy material use

GR1 and GR2 are two American standard material grades. First of all, they belong to the pure titanium series. GR1 has higher purity and better corrosion resistance than GR2. GR1 can be mainly used in places where corrosion resistance is relatively high, plasticity is relatively good, and bending is required, and it can be stamped. GR2 is generally used in chemical equipment for linings, etc., where the requirements are lower than GR1.

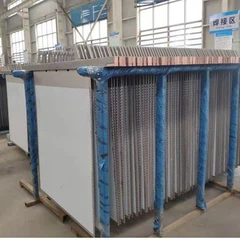

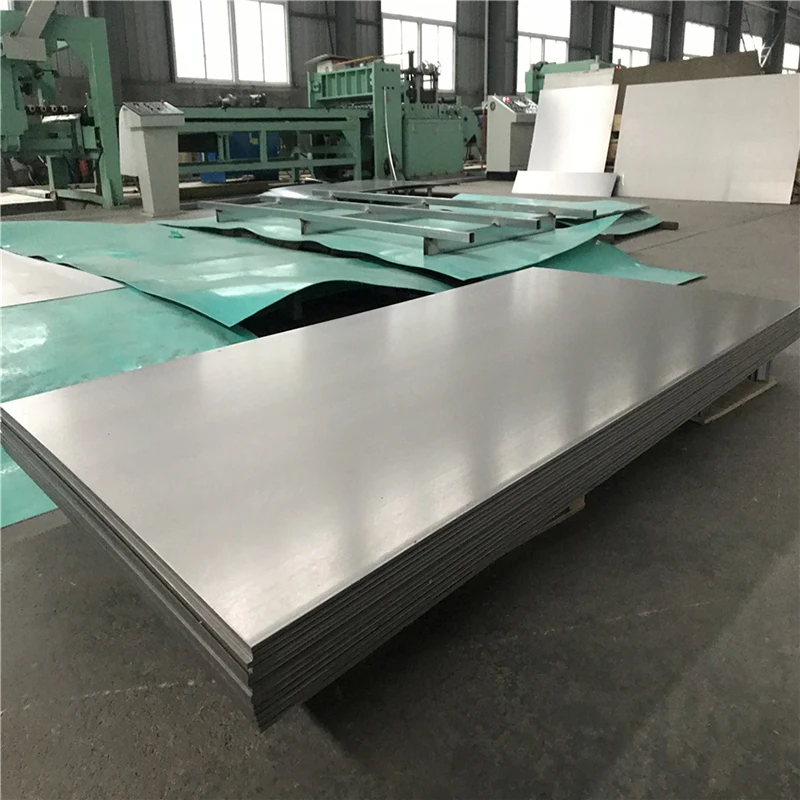

Products Display

Hot Tags: gr1 titanium plate, China gr1 titanium plate manufacturers, suppliers, factory, m7 titanium bolt, gr7 titanium sheet, titanium rod, titanium clad copper bars, titanium welding wire, gr2 titanium plate

You Might Also Like

Send Inquiry