Gr5 ELI Medical Titanium Sheet

Ti (Min):99.5%

Processing Service:Bending, Welding, Decoiling, Cutting, Punching, Machining, Polishing

Shape:Titanium foil strip/titanium sheets plate/titanium coil

Surface:Pickling,Sandblasting, Polished,Mirror

Plate cutting method;Water jet cutting/Wire cutting/Laser cutting etc

Advantage:Corrosion resistance, high strength, high quality.

Material Milling Certificate:Yes

3rd Party Inspection:Yes

Products Description

Medical Titanium Alloy (Medical Titanium)

1. Titanium biomedical materials, are used to manufacture titanium metal for entry-level human medical devices, prostheses, or auxiliary treatment devices.

2. Medical titanium has excellent corrosion resistance, elasticity close to natural bone, and excellent biocompatibility.

3. Medical pure titanium is a single-phase organization and cannot be strengthened by heat treatment.

4. It is divided into 1, 2, 3, and 4 grades according to the content of elements such as carbon, iron, and oxygen.

5. In the middle left bone plate, bone screw, dental implant, etc. Titanium mesh or titanium plate is also used to make artificial skulls, artificial heart valves, pacemakers, titanium alloys for radiotherapy, etc.

Excellent performance of medical titanium plates

Medical titanium plate has low density, lightweight, high strength, good corrosion resistance, high-temperature resistance, low-temperature resistance, strong acid resistance, and strong alkali resistance. Yuanzekai Metal shares the excellent performance of medical titanium rods as follows:

Titanium has strong plasticity. The elongation of high-purity titanium can reach 50-60%, and the cross-sectional shrinkage can reach 70-80%. However, its strength is low and it is not suitable for structural materials. The presence of impurities in titanium has a great influence on its mechanical properties. In particular, interstitial impurities can greatly increase the strength of titanium and significantly reduce its plasticity. The good mechanical properties of medical titanium rods as structural materials are achieved by strictly controlling the appropriate impurity content and adding alloying elements. Titanium has high heat resistance and a melting point of up to 1668 degrees. Titanium is not affected by various strong acids and has strong acid resistance.

Medical titanium plates are used to manufacture titanium alloys for medical devices, prostheses or artificial organs, and auxiliary treatment equipment implanted in the human body. The main alloys include titanium 6 aluminum 4 vanadium, titanium 5 aluminum 2.5 tin, ELI titanium 6 aluminum 4 vanadium, and other alloys. They have a high specific strength, mechanical properties close to human bones, strength far superior to pure titanium, and also have the characteristics of fatigue resistance, corrosion resistance, and excellent biocompatibility.

Medical titanium plates are widely used in various artificial joints, artificial bones, bone fixation devices, dentures, dental inlays, fixed bridges, etc. Medical titanium plates have a wide range of medical uses. In terms of the material of many artificial bone parts, medical titanium plates have become an indispensable part of medical devices.

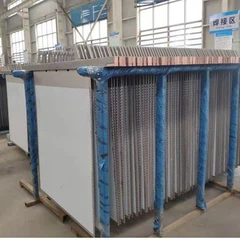

Products display

Hot Tags: gr5 eli medical titanium sheet, China gr5 eli medical titanium sheet manufacturers, suppliers, factory, gr2 titanium tube, titanium machined parts, titanium foil, titanium tube, gr2 titanium plate, molybdenum material

You Might Also Like

Send Inquiry